At the Casters In my previous post, I mentioned that I use a local casting house that allows me to make multiples of my designs and customize the metals for you. Casting metal is an art unto itself and I would rather use a local, family-owned business that will provide their expertise to create the best product for me and of course, for you. Once you read what goes into making a metal casting, I think you’ll agree that it’s best to leave it up to people who specialize in it. :-) My assistant and I recently visited the casting company that I use in the Diamond District of New York to see their process and to show you how one of my models comes alive! If a new piece is being made (like the Brontë earrings), then the first step is to create a silicone mold of the piece. The mold is then cut open to reveal the empty space which is where the wax will go in.  If a silicone mold has already been made, then we will place an order with them for the style, we detail what metal to use, what size is needed and how many. Once the order is received, they pick out the correct molds. In the over 20 years I've been working with Roni Casting, I have quite a few drawers full of molds that I use. There are probably over 300 in total!

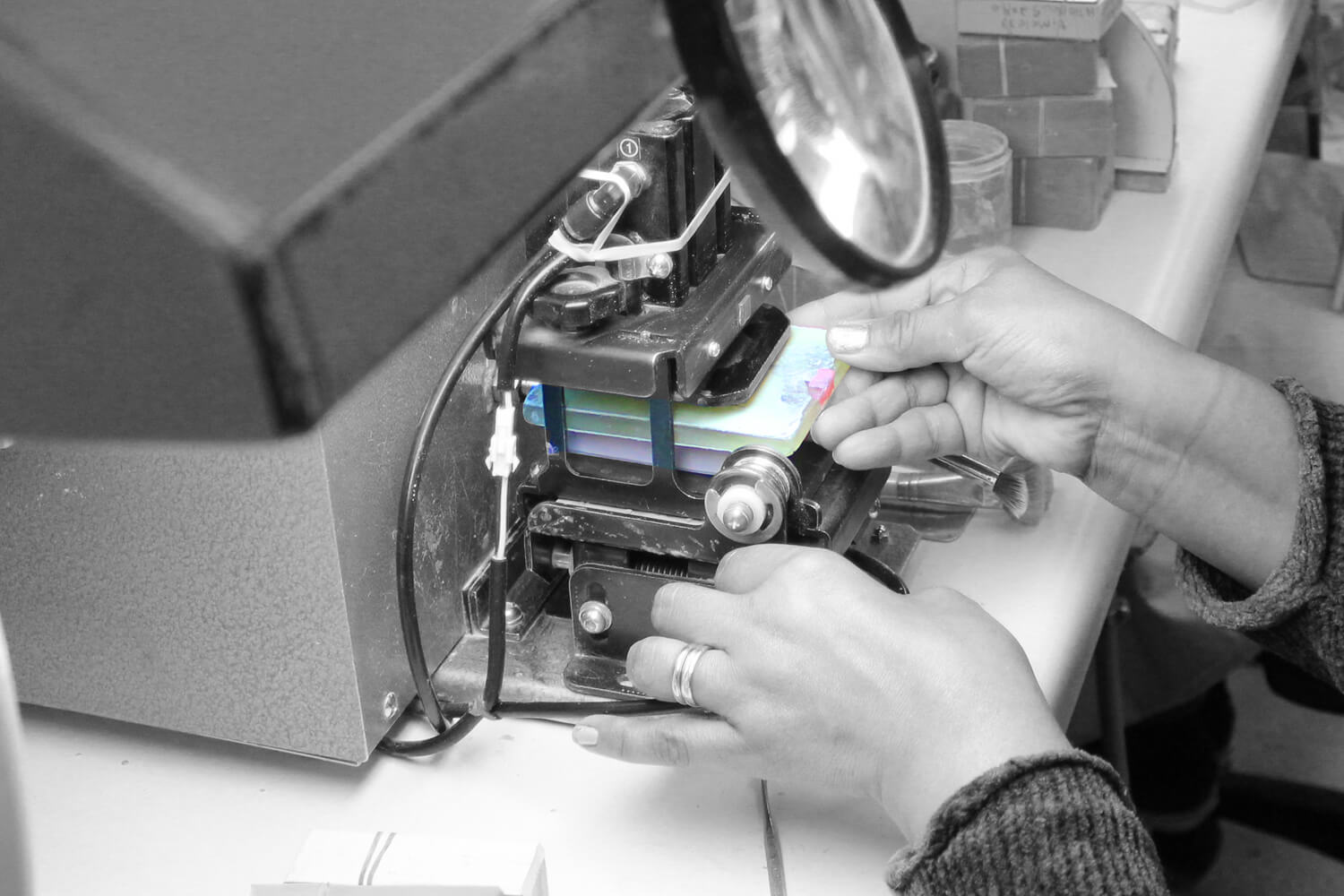

If a silicone mold has already been made, then we will place an order with them for the style, we detail what metal to use, what size is needed and how many. Once the order is received, they pick out the correct molds. In the over 20 years I've been working with Roni Casting, I have quite a few drawers full of molds that I use. There are probably over 300 in total!  Once the correct mold has been selected, it goes to the next stage which is to shoot molten wax into the mold. This is so that multiples of the same piece can be made (in any metal).

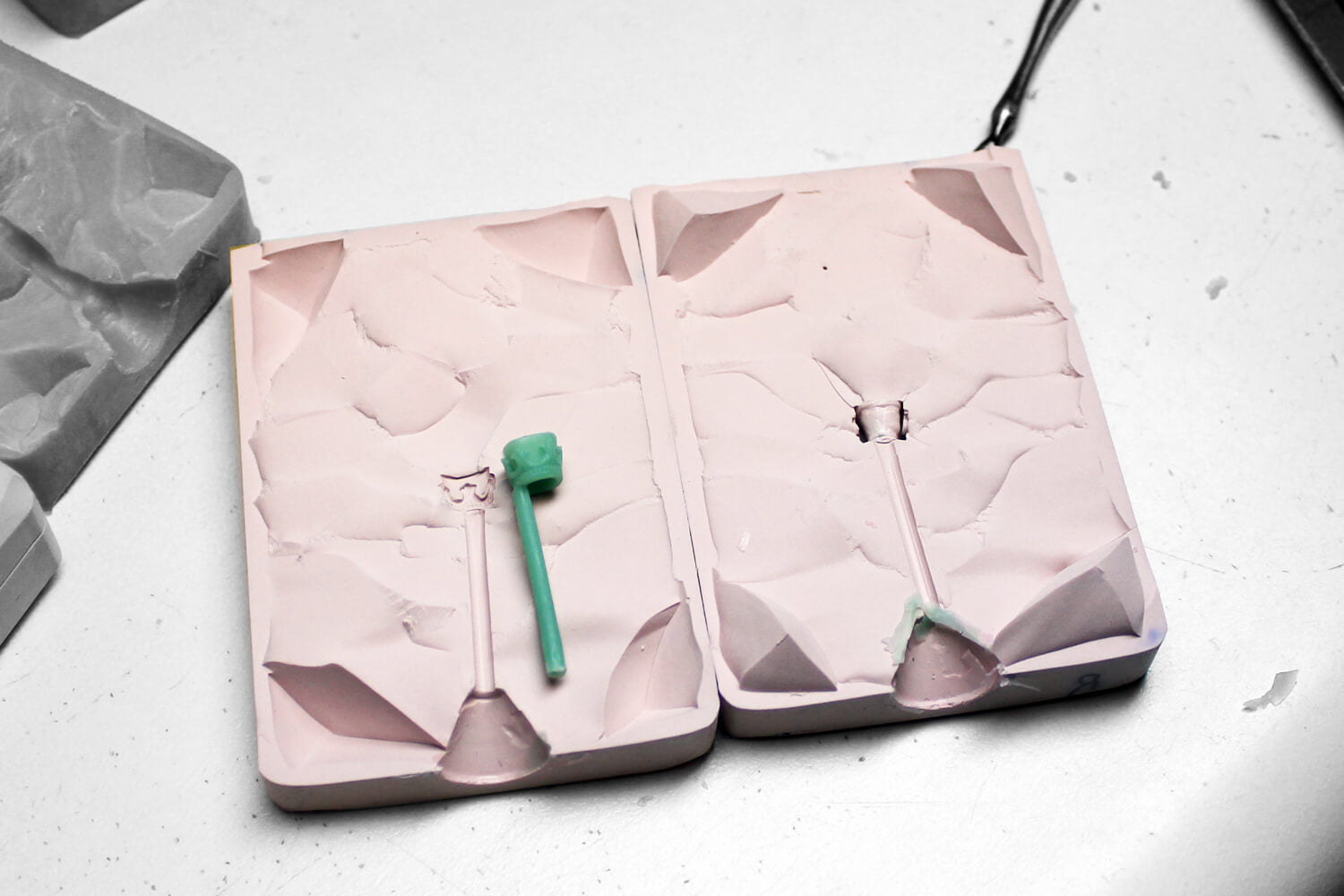

Once the correct mold has been selected, it goes to the next stage which is to shoot molten wax into the mold. This is so that multiples of the same piece can be made (in any metal).  Once the wax is injected, they give it time to cool off before opening the mold. You can see that there is a long rod of wax coming off of the earring bezel. This rod is called the sprue and you'll see why we need it later on.

Once the wax is injected, they give it time to cool off before opening the mold. You can see that there is a long rod of wax coming off of the earring bezel. This rod is called the sprue and you'll see why we need it later on.  It’s then over to the next station where they inspect the wax to make sure it’s complete, and if necessary, clean up and resize the wax (say for a ring).

It’s then over to the next station where they inspect the wax to make sure it’s complete, and if necessary, clean up and resize the wax (say for a ring).  Once the waxes have been inspected, they are ready to be added to what is called a tree. Imagine that there is center “trunk” which the sprues of the waxes are attached to. This is then placed in a flask and a special mixture of plaster investment is poured into it. Once the investment is dry, the flask is taken to a kiln and left overnight for the waxes to drip out of the flask, leaving a negative space where the wax once was. This is where the metal will be poured into.

Once the waxes have been inspected, they are ready to be added to what is called a tree. Imagine that there is center “trunk” which the sprues of the waxes are attached to. This is then placed in a flask and a special mixture of plaster investment is poured into it. Once the investment is dry, the flask is taken to a kiln and left overnight for the waxes to drip out of the flask, leaving a negative space where the wax once was. This is where the metal will be poured into.  The metal is heated to a high temperature which differs depending on the metal and alloys used and then it's poured into the flask. The molten metal fills in the cavities of the wax tree (remember that the wax was melted out in the ovens overnight).

The metal is heated to a high temperature which differs depending on the metal and alloys used and then it's poured into the flask. The molten metal fills in the cavities of the wax tree (remember that the wax was melted out in the ovens overnight).

Once the pieces have been cooled, the investment is washed off . You're left with just the tree that's now in the metal that was poured into it. The sprues are then snipped off (which need to be sawn off and filed down even further by me in my studio).

Once the pieces have been cooled, the investment is washed off . You're left with just the tree that's now in the metal that was poured into it. The sprues are then snipped off (which need to be sawn off and filed down even further by me in my studio).  They are then inspected once more, to check for any defects like porosity (where parts of the metal did not get to all the areas of the negative space in the flask and leave behind tiny pits in the metal). They are then weighed to ensure that the market rate for that day for the type of metal is used and then they are ready to be picked up by the Metalicious team! As you can see there are a lot of steps to create just one piece, and that doesn't even include the stone setting and polishing! We counted that each piece goes through around 15 sets of hands at the casters alone! We made a video so you can really get a good look at the process: Fun Facts: (well fun to me anyway) We asked which metal is their most popular and by and far it’s sterling silver. They cast around 150 trees per day (each tree can have up to 50 pieces on, depending on size of piece). They can cast in all the usual metals from silver to gold to palladium to platinum, plus stainless steel and aluminum. Their largest order (not by us!) was for 35,000 rings in sterling silver which were all sold in just 45 mins on QVC! Some inspiration from the new collection: “I have dreamt in my life, dreams that have stayed with me ever after, and changed my ideas; they have gone through and through me, like wine through water, and altered the color of my mind.” E Brontë, Wuthering Heights Hope you found this interesting (I could talk about jewelry all day).

They are then inspected once more, to check for any defects like porosity (where parts of the metal did not get to all the areas of the negative space in the flask and leave behind tiny pits in the metal). They are then weighed to ensure that the market rate for that day for the type of metal is used and then they are ready to be picked up by the Metalicious team! As you can see there are a lot of steps to create just one piece, and that doesn't even include the stone setting and polishing! We counted that each piece goes through around 15 sets of hands at the casters alone! We made a video so you can really get a good look at the process: Fun Facts: (well fun to me anyway) We asked which metal is their most popular and by and far it’s sterling silver. They cast around 150 trees per day (each tree can have up to 50 pieces on, depending on size of piece). They can cast in all the usual metals from silver to gold to palladium to platinum, plus stainless steel and aluminum. Their largest order (not by us!) was for 35,000 rings in sterling silver which were all sold in just 45 mins on QVC! Some inspiration from the new collection: “I have dreamt in my life, dreams that have stayed with me ever after, and changed my ideas; they have gone through and through me, like wine through water, and altered the color of my mind.” E Brontë, Wuthering Heights Hope you found this interesting (I could talk about jewelry all day).

Behind the Scenes